Blog

Understanding Rigid Flex PCBs: A Comprehensive Guide to This Hybrid Technology

In recent years, the demand for advanced electronics has driven significant innovations in printed circuit board (PCB) technologies, with rigid flex PCBs emerging as a prominent player in this space. According to a report by ResearchAndMarkets, the global rigid flex PCB market is expected to grow at a CAGR of 12.3% from 2021 to 2026, highlighting their increasing adoption across various industries such as aerospace, automotive, and consumer electronics. This hybrid technology combines the best of both rigid and flexible boards, offering enhanced design flexibility, reduced weight, and increased reliability. As designers and manufacturers strive for more compact and efficient electronic solutions, understanding rigid flex PCBs is essential in leveraging their unique advantages in modern applications. This comprehensive guide will unravel the intricacies of rigid flex PCBs, providing insights into their construction, benefits, and key considerations for implementation.

What Are Rigid Flex PCBs and How Do They Work?

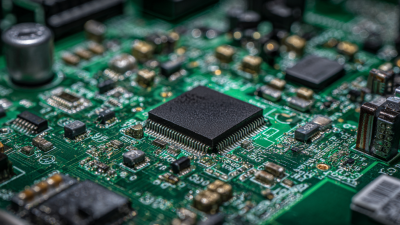

Rigid flex PCBs represent an innovative approach at the intersection of rigid and flexible circuit board technologies. These hybrid boards combine the advantages of both types, providing enhanced design flexibility and durability, which makes them ideal for modern electronic applications. A rigid flex PCB consists of multiple layers where rigid sections are joined to flexible segments, allowing for effective compact designs that can fit within limited spaces while maintaining structural integrity.

Tips for optimizing your design include considering the layout meticulously; ensure that the transition between rigid and flexible areas is smooth to prevent stress points. Additionally, selecting appropriate materials is crucial; recent advancements have introduced biodegradable substrates that not only promote sustainability but also enhance performance. Furthermore, incorporating innovative joining technologies can improve reliability in applications, especially in electronic textiles.

As the PCB industry is expected to thrive between 2025 and 2027, understanding the functionalities of rigid flex PCBs will be integral to leveraging their benefits. Keeping abreast of trends such as micromachined ultrasound transducers and stretchable circuit boards can inform future design strategies, pushing the boundaries of what these hybrid circuits can achieve in sectors like biomedical applications.

Understanding Rigid Flex PCBs: A Comprehensive Guide to This Hybrid Technology

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Material Composition | Combination of rigid substrates with flexible sections. | Increased design flexibility and reduced overall weight. | Mobile devices, aerospace, and medical devices. |

| Manufacturing Process | Multi-step process involving layering and lamination. | Enhanced reliability with improved circuit interconnections. | Consumer electronics, automotive systems. |

| Design Complexity | Can be designed in complex shapes and sizes. | Allows for more compact and integrated designs. | Wearable technology, drones. |

| Cost Consideration | Higher initial production costs than traditional PCBs. | Long-term savings due to reduced assembly time. | Advanced electronics, industrial equipment. |

Key Advantages of Rigid Flex PCBs Over Traditional Circuit Boards

Rigid flex PCBs are revolutionizing the electronics industry by offering a unique combination of rigid and flexible properties. One of the key advantages of these hybrid circuit boards is their ability to save space without compromising performance. In applications where size and weight are critical, such as in smartphones, wearables, and aerospace devices, rigid flex PCBs allow for a more compact design by integrating multiple functions into a single board. This integration not only reduces the number of components but also enhances reliability by minimizing the potential failure points associated with interconnections.

Another significant benefit of rigid flex PCBs is their improved durability. Unlike traditional circuit boards, which can be prone to damage from bending or flexing, rigid flex designs are engineered to withstand mechanical stress. This resilience makes them ideal for dynamic applications, where frequent movement occurs, such as in medical devices and robotic systems. By utilizing rigid flex technology, manufacturers can achieve enhanced performance and longevity in their products, ultimately leading to lower maintenance costs and increased customer satisfaction.

Key Advantages of Rigid Flex PCBs Over Traditional Circuit Boards

Applications of Rigid Flex PCBs in Modern Electronics

Rigid Flex PCBs are gaining significant traction in modern electronics due to their unique combination of the benefits offered by both rigid and flexible printed circuit boards. These hybrid technologies offer excellent design flexibility, reduced weight, and improved reliability, making them ideal for a wide range of applications from smartphones to medical devices. The ability of Rigid Flex PCBs to save space and support complex circuitry allows manufacturers to push the boundaries of product innovation.

In recent years, the demand for Rigid Flex PCBs has surged as industries seek to deliver more compact and efficient electronic solutions. The automotive sector, particularly with the rise of electric vehicles, is increasingly adopting this technology for its ability to withstand harsh environments while maintaining performance. Additionally, consumer electronics continue to be a major market for Rigid Flex PCBs, as manufacturers aim for lighter and more versatile designs.

Tips: When considering Rigid Flex PCBs for your next project, ensure that the design accommodates the specific application needs, such as thermal management and mechanical stress. Additionally, collaborating with experienced manufacturers can help you navigate the complexities of production and achieve the optimal balance between performance and cost.

Design Considerations for Rigid Flex PCB Manufacturing

When embarking on the manufacturing journey of rigid flex PCBs, several design considerations are pivotal to ensuring success. First and foremost, understanding the physical space constraints and mechanical requirements of the final product is essential. Rigid flex PCBs offer flexibility that allows them to fit into various confined spaces; however, the design must strategically allocate components for optimal performance and reliability.

Tip: Always prioritize the placement of components that experience the most stress during flexing. This will mitigate mechanical fatigue and enhance overall durability.

Another key consideration is material selection. The choice of flexible substrate can significantly affect the PCB's lifetime and functionality. Materials like polyimide and polyester are commonly used due to their excellent thermal and mechanical properties. Additionally, the chosen material should align with the environmental conditions the PCB will face.

Tip: Conduct thorough testing of materials under expected operational conditions to ensure that they can withstand temperature variations and mechanical stress.

Lastly, the manufacturing process plays a crucial role in the performance of rigid flex PCBs. Techniques such as layering and bonding should be examined closely to prevent delamination and ensure signal integrity. Engaging with manufacturers who specialize in rigid flex technology will aid in navigating these complexities.

Tip: Collaborate with your PCB manufacturer early in the design phase to identify potential challenges and streamline the production process.

Future Trends and Innovations in Rigid Flex Technology

The evolution of rigid-flex printed circuit boards (PCBs) is steering the future of electronics towards greater efficiency and flexibility. As industries continue to demand lighter, thinner, and more complex devices, rigid-flex technology stands at the forefront, combining the benefits of both rigid and flexible circuits. Future innovations in this field promise enhancements in materials, manufacturing processes, and application areas, paving the way for the next generation of electronic devices.

One significant trend is the integration of advanced materials, such as high-frequency substrates and new polymer technologies, which can improve performance and reliability. Companies are investing in research to develop eco-friendly materials that not only comply with regulatory standards but also reduce the overall ecological footprint of electronics.

Tip: When selecting rigid-flex PCBs for your project, consider the specific requirements of your design, such as size constraints and environmental factors, to ensure optimal performance. Additionally, stay updated on emerging technologies that might offer enhanced capabilities or reduce costs.

Moreover, the move towards automation in the manufacturing process is expected to streamline production, reduce lead times, and lower costs. As AI and machine learning applications evolve, these technologies will enable smarter production lines, ensuring higher consistency and quality in rigid-flex PCBs.

Tip: Collaborate closely with your PCB manufacturer to leverage their expertise in materials and processes, ensuring that your design aligns with the best production practices and the latest innovations in the rigid-flex domain.

Related Posts

-

Envisioning Tomorrow: The Rise of Best Rigid Flex PCB in Modern Electronics

-

How to Optimize Your Supply Chain with Rigid Flex Solutions for Global Sourcing

-

The Definitive Ultimate Guide to Sourcing and Using Flex Circuits for Global Buyers

-

7 Essential Reasons Why Rigid Flex Technology Is Transforming Modern Electronics

-

Unlocking the Advantages of Using Prototype PCB Boards in Modern Electronics Design

-

How to Choose the Best PCB Board for Your Project Needs