Blog

Understanding the Role of Circuit Board Manufacturing in Modern Electronics

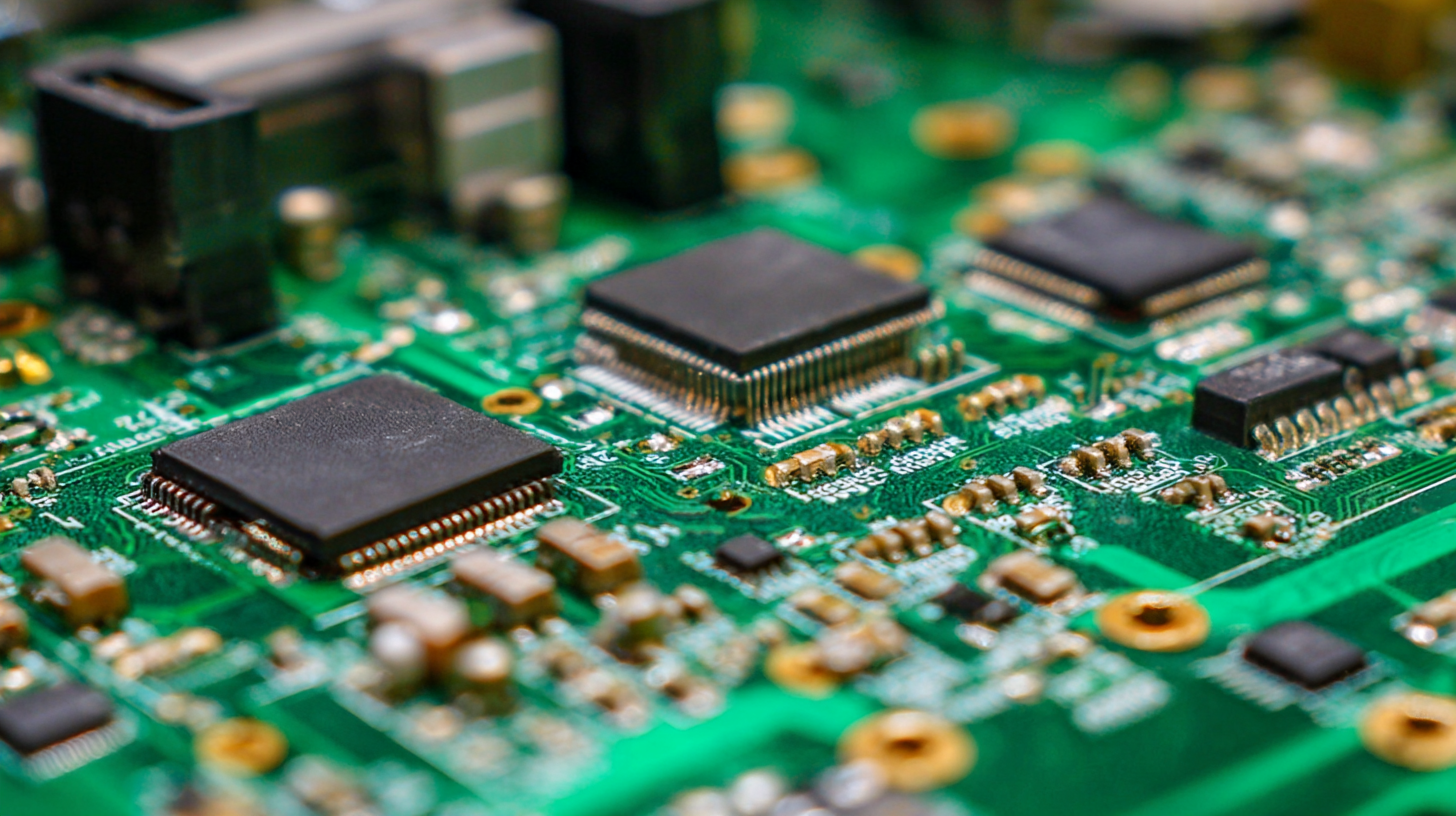

Circuit board manufacturing is a critical backbone of modern electronics, serving as the essential platform where innovation meets practical application. As technology continues to evolve at a rapid pace, understanding the intricacies of circuit board manufacturing has become increasingly important for developers, engineers, and manufacturers alike. This process not only involves the creation of the electronic boards that power virtually all devices, from smartphones to sophisticated industrial equipment, but also intertwines with advancements in materials, design strategies, and production techniques. In this guide, we will explore the fundamental aspects of circuit board manufacturing, delve into best practices, and highlight key considerations that can significantly impact the performance and reliability of electronic products. Whether you are a newcomer or a seasoned professional in the electronics field, this comprehensive overview will equip you with the necessary insights to enhance your knowledge and proficiency in circuit board manufacturing.

The Importance of Circuit Boards in Electronic Devices

Circuit boards are the backbone of modern electronic devices, playing a critical role in their functionality and efficiency. According to a recent market report by Research and Markets, the global printed circuit board (PCB) market is projected to reach $75.8 billion by 2027, growing at a CAGR of 4.2% from 2020. This growth underscores their importance not only in consumer electronics like smartphones and laptops but also in essential sectors such as automotive and healthcare, where reliability and performance are paramount.

The increasing complexity of electronic systems has driven innovation in circuit board manufacturing techniques. Advanced materials and manufacturing processes enable the production of more compact and efficient boards, facilitating the miniaturization of devices. IPC, the Association Connecting Electronics Industries, emphasizes that over 50% of the cost of electronic systems is linked to the design and manufacturing of PCBs. This statistic highlights the integral role that circuit boards play in reducing overall expenses while improving the functionality of electronic devices, further demonstrating their importance in the competitive tech landscape.

Key Manufacturing Processes in Circuit Board Production

The manufacturing of circuit boards is a cornerstone of modern electronics, and it involves several key processes that ensure precision and quality. One of the primary steps is the design and layout of the circuit board, where engineers use specialized software to create intricate patterns that will later guide the electrical connections. This phase is crucial as it determines the board's functionality and efficiency.

Next comes the actual fabrication of the boards, which typically involves processes like etching and drilling. During etching, unwanted copper is removed from the surface of the board, revealing the desired circuit design. Drilling creates holes for components to be inserted. It is essential to maintain strict quality control throughout these stages to prevent defects that could impair the performance of the final product.

Tip: For anyone looking to enhance the quality of circuit boards, consider implementing advanced testing techniques such as Automated Optical Inspection (AOI). This can identify issues early in the manufacturing process, reducing waste and ensuring reliability.

Another critical process is soldering, where components are secured onto the board. This can be accomplished through wave soldering or reflow soldering, depending on the complexity of the assembly. Proper soldering techniques are vital for ensuring strong electrical connections and preventing future failures.

Tip: Ensure that the workspace is clean and well-organized during soldering to minimize contamination and ensure optimal performance of the electronic devices.

Materials Used in Modern Circuit Board Manufacturing

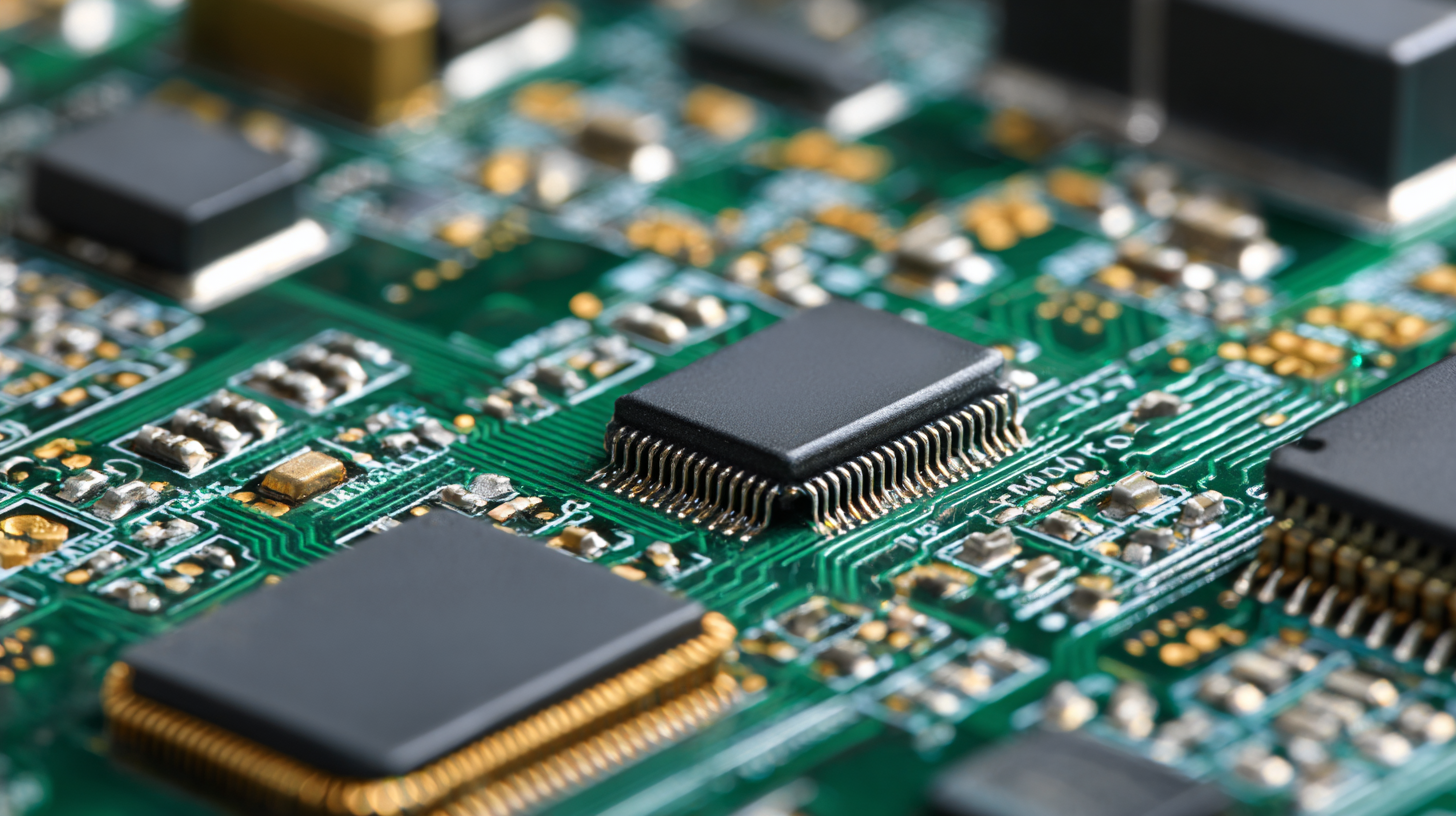

In the realm of modern electronics, the manufacturing of circuit boards serves as a pivotal foundation for countless devices. The materials chosen for this process play a critical role in defining not just performance but also the reliability of the final product. Common materials include epoxy resin, fiberglass, and various metals like copper. These components are not only essential for providing insulation and structural integrity but also for ensuring efficient electrical conductivity.

When selecting materials for circuit board manufacturing, consider opting for high-quality epoxy resins as they offer excellent thermal stability and resistance to environmental stressors. Additionally, incorporating advanced materials like polyimide can enhance performance in high-temperature applications.

Always keep in mind that while the initial cost of premium materials might be higher, the long-term benefits—such as improved durability and performance—often outweigh these upfront expenses. Investing in the right materials ensures that the final circuit board can withstand the rigors of modern electronic demands.

Understanding the Role of Circuit Board Manufacturing in Modern Electronics - Materials Used in Modern Circuit Board Manufacturing

| Material Type | Description | Applications | Properties |

|---|---|---|---|

| FR-4 | A composite material made of woven fiberglass cloth with an epoxy resin. | Most common PCB substrate for general-purpose applications. | Good electrical insulation, heat resistance, and mechanical strength. |

| Polyimide | Thermal-resistant polymer used for flexible circuit boards. | Flexible PCBs, aerospace, and high-temperature applications. | Excellent thermal stability and good electrical properties. |

| Alumina | High-purity ceramic material for high-frequency circuits. | RF and microwave applications, LED packages. | High thermal conductivity, electrical insulation, and mechanical stability. |

| CEM-1 | Composite material combining paper and epoxy resin. | Single-sided PCBs in consumer electronic devices. | Cost-effective with decent mechanical and electrical properties. |

| Metal Core | PCBs with a metal base for better heat dissipation. | LED lighting and power electronics. | Excellent thermal conductivity and heat distribution. |

Challenges and Innovations in Circuit Board Technology

The landscape of circuit board manufacturing is rapidly evolving, driven by the demands of modern electronics. Challenges such as miniaturization, increased functionality, and cost efficiency continue to pressure manufacturers. According to a report by the IPC, the global printed circuit board (PCB) market is expected to reach USD 79.5 billion by 2026, highlighting the industry's crucial role in supporting technological advancements. As electronics become smaller and more intricate, manufacturers are increasingly adopting advanced technologies like HDI (High-Density Interconnect) and flexible PCBs, which enhance performance while addressing space constraints.

Moreover, sustainability is emerging as a pressing concern within the circuit board industry. Recent studies indicate that around 70% of electronic waste comes from discarded circuit boards, leading to significant environmental challenges. Innovations such as eco-friendly materials and processes are now being prioritized. A report by Research and Markets suggests the market for environmentally-friendly PCB materials will witness a growth rate of over 10% annually over the next five years. This trend reflects not only a response to regulatory pressures but also a growing consumer demand for sustainable electronics, pushing manufacturers to innovate in ways that are both functional and responsible.

Impact of Circuit Board Quality on Overall Device Performance

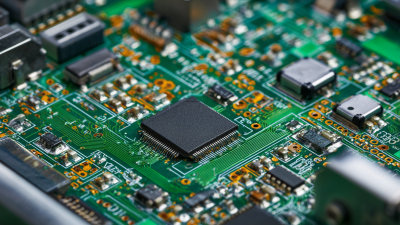

The quality of circuit boards plays a crucial role in the overall performance of electronic devices. A well-manufactured circuit board ensures reliable connections, minimizes signal loss, and enhances the longevity of the device. Conversely, poor quality circuit boards can lead to malfunctions, increased power consumption, and ultimately, device failure. Therefore, investing in high-quality PCB fabrication is essential for anyone looking to enhance their product's reliability and efficiency.

Tips: When selecting a PCB manufacturer, look for those that adhere to the latest industry standards and certifications. Additionally, evaluate their track record for quality assurance and customer service. Regular inspections and testing during the manufacturing process can also help mitigate risks associated with circuit board failures.

It’s also important to consider the materials used in circuitry. High-grade materials not only improve conductivity but also provide better thermal management, which is critical for high-performance devices. Choosing the right substrate and finishes can significantly impact the signal integrity and overall durability of the circuit board.

Tips: Always ask potential manufacturers about the types of materials they use and their sourcing practices. Consider establishing a collaborative approach so that you can share your specific performance needs, allowing manufacturers to provide tailored solutions that enhance device performance.

Related Posts

-

Understanding the Industry Standards Challenges for Best PCB Circuit Production

-

Ultimate Guide to Choosing the Right Electronic Board: Key Metrics and Insights for Success

-

Mastering Flexible Printed Circuits: A Comprehensive Step-by-Step Guide for Beginners

-

Embracing Innovation: The Future of PCB Printed Circuit Board Technology and Applications

-

Discover the Excellence of Best PCB Make from Top Quality Manufacturers in China

-

Solutions for Sourcing the Best PCB Circuit Boards Globally: Your Comprehensive Guide