Blog

10 Insights on Flexible Printed Circuit Boards for Enhanced Electronic Performance

Flexible printed circuit boards (FPCBs) have emerged as a pivotal technology in the ever-evolving landscape of electronics, offering remarkable advantages in enhancing performance across a myriad of applications, from consumer electronics to industrial machinery. According to a recent market analysis by Mordor Intelligence, the global flexible printed circuit board market is expected to reach USD 41.06 billion by 2026, growing at a CAGR of 10.3%. This surge can be attributed to the increasing demand for miniaturization in electronic devices and the shift towards lightweight, space-saving solutions. In essence, the flexibility of these circuit boards allows for innovative designs and improved efficiency, making them integral to the advancement of technologies such as wearable devices, IoT systems, and automotive electronics. By exploring ten key insights into flexible printed circuit boards, we can better understand their impact on electronic performance and their critical role in shaping the future of technology.

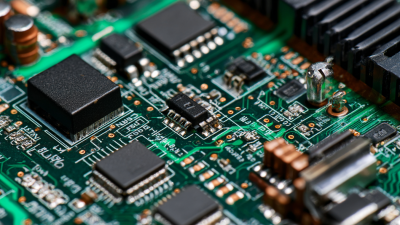

Understanding the Fundamentals of Flexible Printed Circuit Boards

Flexible Printed Circuit Boards (FPCBs) have revolutionized the electronics industry by enabling more compact and lightweight designs while maintaining high performance. The fundamental concept behind FPCBs lies in their ability to bend and twist without compromising integrity, which is crucial for modern electronic devices that demand versatility and durability.

These circuits are constructed from flexible substrates, typically polyimide or polyester, allowing them to conform to complex shapes and fit into tight spaces.

One of the key advantages of FPCBs is their capacity to enhance connectivity in multi-layer designs, minimizing the need for traditional wiring. This not only reduces the size and weight of electronic assemblies but also improves reliability by decreasing the risk of mechanical failure due to movement or vibration.

Understanding the materials and manufacturing processes involved in FPCB production is essential for engineers looking to leverage their benefits effectively. As technology continues to advance, the role of flexible printed circuit boards in enhancing electronic performance will undoubtedly expand, pushing the boundaries of what is possible in device design and functionality.

Key Benefits of Using Flexible Printed Circuit Boards in Electronics

Flexible Printed Circuit Boards (FPCBs) have become increasingly essential in the electronics industry, offering significant advantages over traditional rigid circuitry. One of the primary benefits is their lightweight and compact design. According to a report by MarketsandMarkets, the global flexible printed circuit board market is projected to grow from USD 16.1 billion in 2020 to USD 26.4 billion by 2025, indicating a growing acceptance of FPCBs in various applications such as smartphones, wearable devices, and automotive electronics. This trend underscores the crucial role that flexibility plays in modern electronic design, enabling manufacturers to save space and reduce the overall weight of devices.

In addition to their size and weight advantages, FPCBs exhibit enhanced durability and reliability. They are less prone to breakage and can withstand harsh environmental conditions, making them ideal for applications in automotive and aerospace industries. A study published by IDTechEx highlights that the implementation of flexible circuits can improve product performance by reducing the risk of mechanical failure. This reliability is critical as electronic devices become smaller and more integrated, allowing for greater design freedom and increased functionality while maintaining the resilience necessary for high-performance applications.

10 Insights on Flexible Printed Circuit Boards for Enhanced Electronic Performance

| Benefit | Description | Applications |

|---|---|---|

| Space Saving | Flexible PCBs can be bent and shaped, allowing for more compact designs. | Wearable devices, mobile phones |

| Lightweight | Reduced weight compared to rigid PCBs enhances portability. | Aerospace, medical instruments |

| Flexibility | Can be integrated into curved surfaces or tight spaces. | Consumer electronics, automotive displays |

| Improved Reliability | Less susceptible to vibration and mechanical stress. | Industrial equipment, military applications |

| Cost Efficiency | Lower assembly costs due to flexibility in design and manufacturing. | High-volume consumer products, electronics |

| Enhanced Thermal Management | Better heat dissipation compared to traditional PCBs. | LED lighting, power electronics |

| Design Versatility | Can accommodate various electronic components with ease. | Smart devices, IoT products |

| Better Signal Integrity | Shorter interconnection lengths reduce signal loss. | High-frequency applications, telecommunications |

| Environmental Resilience | Can withstand harsh environmental conditions. | Automotive, outdoor equipment |

| Rapid Prototyping | Easier and faster to develop prototypes due to flexible nature. | Research and development, custom electronics |

Design Considerations for Optimal Performance of Flexible Circuits

When designing flexible printed circuit boards (FPCBs), several key considerations are essential to ensure optimal electronic performance. One of the primary factors is the choice of substrate materials. According to a report by MarketsandMarkets, the flexible circuit market is projected to reach $30 billion by 2025, driven by advancements in materials that enhance flexibility and thermal stability. Polyimide remains a leading choice due to its outstanding thermal properties and mechanical strength, making it suitable for high-temperature applications.

When designing flexible printed circuit boards (FPCBs), several key considerations are essential to ensure optimal electronic performance. One of the primary factors is the choice of substrate materials. According to a report by MarketsandMarkets, the flexible circuit market is projected to reach $30 billion by 2025, driven by advancements in materials that enhance flexibility and thermal stability. Polyimide remains a leading choice due to its outstanding thermal properties and mechanical strength, making it suitable for high-temperature applications.

Another critical aspect is the layout and routing of traces on the PCB. A well-optimized layout minimizes excessive bending stress and ensures signal integrity. As noted in a study published by IPC, improper routing can lead to increased electromagnetic interference (EMI) and signal degradation, which can significantly affect device performance. Designers should also consider the use of solder mask and surface finish options that enhance durability and performance in dynamic environments. By implementing these design considerations, manufacturers can leverage the full capabilities of flexible circuits in various applications, from consumer electronics to aerospace.

Innovative Applications of Flexible Printed Circuit Boards in Modern Devices

Flexible printed circuit boards (FPCBs) have emerged as vital components in modern electronic devices, revolutionizing the way we design and integrate technology. Their unique properties, such as lightweight construction and the ability to bend and mold into various shapes, allow for innovative applications across diverse sectors. In wearable technology, for instance, FPCBs facilitate compact designs that conform to the body’s natural movements, enhancing user comfort and functionality. This adaptability is crucial for devices like fitness trackers and smartwatches, where space is limited, yet performance remains a paramount concern.

Moreover, FPCBs are playing a significant role in the advancement of medical devices. Their flexibility and reliability enable the development of minimally invasive tools and implants that can conform to the complex geometries of the human body. This medical innovation not only improves patient outcomes but also paves the way for more sophisticated diagnostic equipment and treatments. As the demand for miniaturization and multi-functionality in electronic devices grows, the applications of flexible printed circuit boards will continue to expand, providing enhanced performance and opening doors to new technological frontiers.

Future Trends in Flexible Printed Circuit Technology and Performance Enhancements

The landscape of flexible printed circuit (FPC) technology is undergoing significant transformations, driven by the increasing demand for compact and lightweight electronic devices. One prominent trend is the integration of advanced materials that enhance durability and thermal performance. These materials not only improve the lifespan of FPCs but also enable them to withstand extreme conditions, making them suitable for a broader range of applications, from wearable electronics to aerospace systems.

Another key trend is the ongoing miniaturization of electronic components. With the relentless push for smaller, more efficient devices, the development of high-density interconnect (HDI) FPCs is becoming essential. This evolution allows for more complex circuit designs without compromising on flexibility. Furthermore, advancements in manufacturing techniques, such as additive printing and laser processing, are paving the way for rapid prototyping and cost-effective production, ensuring that flexibility doesn't come at the expense of performance. As these technologies continue to evolve, the future of flexible printed circuits looks promising, oriented towards enhanced electronic performance and broader application scopes.

Performance Metrics of Flexible Printed Circuit Boards (FPCBs)

This chart illustrates various performance metrics of Flexible Printed Circuit Boards (FPCBs), highlighting their strengths in thermal conductivity, flexibility, weight, cost-effectiveness, and signal integrity. The scores reflect the importance of these factors in enhancing the overall electronic performance of FPCBs, showcasing their role in future electronic applications.

Related Posts

-

Understanding Rigid Flex PCBs: A Comprehensive Guide to This Hybrid Technology

-

Solutions for Sourcing the Best PCB Circuit Boards Globally: Your Comprehensive Guide

-

Unlocking the Advantages of Using Prototype PCB Boards in Modern Electronics Design

-

How to Choose the Right PCB Circuit Board for Your Project Needs

-

How to Optimize Your Supply Chain with Rigid Flex Solutions for Global Sourcing

-

Discover the Excellence of Best PCB Make from Top Quality Manufacturers in China