Blog

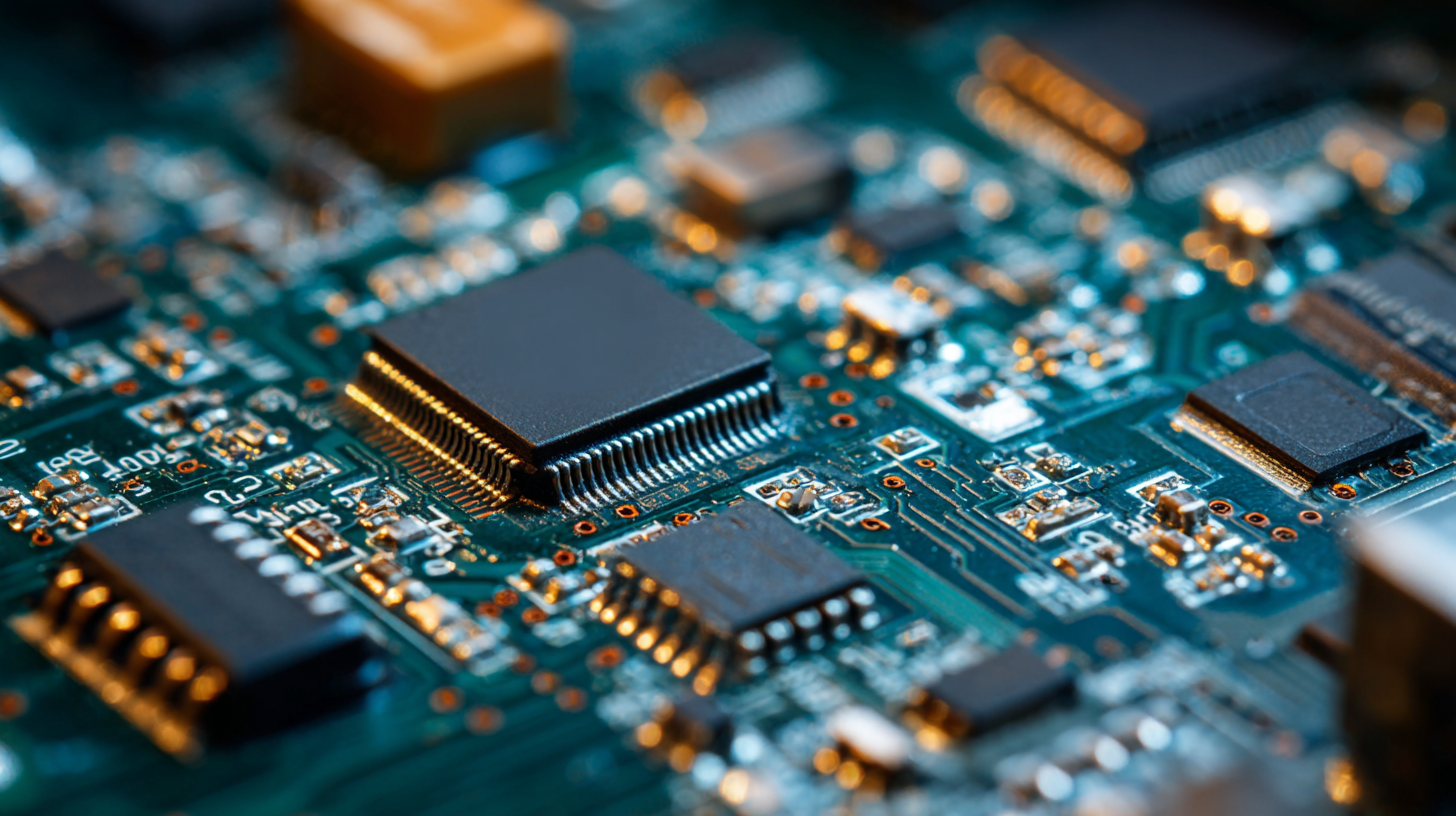

Exploring the Evolution of Circuit Boards: From Early Days to Modern Innovations

The evolution of circuit boards is a fascinating journey that mirrors the rapid advancements in technology over the decades. From their inception in the early 20th century, when simple conductive paths were hand-drawn on bakelite, to today's complex multi-layered boards that power everything from smartphones to advanced computing systems, circuit boards have become a cornerstone of modern electronics.

According to a report by Research and Markets, the global printed circuit board (PCB) market is projected to reach USD 82.4 billion by 2026, growing at a CAGR of 3.8%. This growth is fueled by the increasing demand for innovative electronic devices and the advancement of smart technologies.

As we explore the history and innovations in circuit board design, we uncover not only the technical challenges overcome by engineers but also the profound impact of these developments on various industries and daily life.

The Origins of Circuit Boards: A Historical Perspective

The origins of circuit boards can be traced back to the early 20th century when the demand for more efficient electrical connectivity began to rise. Initially, circuits were constructed using point-to-point wiring, which was not only cumbersome but also prone to errors. The need for a more reliable and compact solution led to the development of printed circuit boards (PCBs) in the 1930s. An important milestone came in 1943 when the invention of the PCB was patented by Paul Eisler, who envisioned a method of embedding conductive tracks onto insulating materials, drastically transforming electronic design.

Throughout the mid-20th century, circuit boards evolved alongside advances in technology. The post-war era saw an explosion in consumer electronics, driving the demand for reliable and cost-effective manufacturing processes. The introduction of mass production techniques and the advent of new materials allowed for more complex circuit designs, enabling devices to become smaller and more powerful. By the 1970s, multilayer circuit boards emerged, allowing for compact design without compromising functionality. This evolution laid the groundwork for the sophisticated circuit boards we rely on today in everything from computers to smartphones, underscoring the critical role of circuit boards in modern innovation.

Key Components and Materials: Building Blocks of Early Circuit Boards

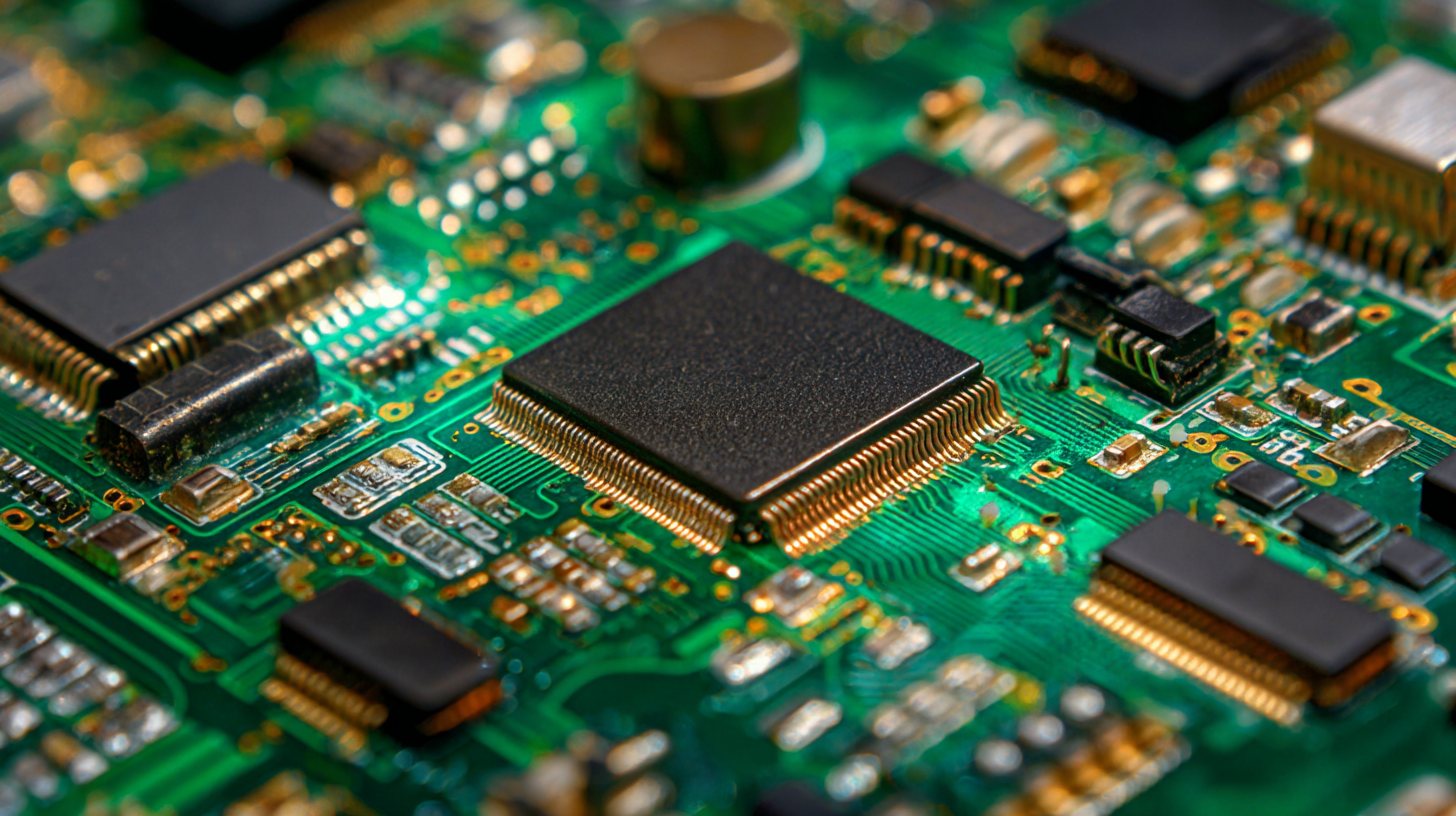

The evolution of circuit boards has revolutionized the world of electronics, and understanding the key components and materials that formed the foundation of early circuit boards is essential. Early circuit boards primarily utilized basic materials such as bakelite and paper phenolic that were both durable and easy to manufacture. These materials provided a sturdy base for components like resistors, capacitors, and, later, integrated circuits, which were the fundamental building blocks of early electronic devices. The selection of materials was crucial for the reliability and performance of the circuit boards, significantly impacting their functionality.

**Tips:** When designing a circuit board, consider starting with a simple layout to better understand the flow of electricity. Additionally, using high-quality materials, even for prototyping, can enhance the longevity and performance of your board.

As technology advanced, materials evolved to include fiberglass-reinforced epoxy, which allowed for more complex designs and miniaturization of components. This transition not only improved the durability of circuit boards but also enabled the development of multilayer boards, which have become a standard in modern electronics. Understanding these materials helps highlight the shift from functionality to enhanced performance and efficiency in circuit design.

**Tips:** Explore various PCB design software tools that can help visualize and optimize your circuit layout, making it easier to incorporate modern innovations into your projects.

Exploring the Evolution of Circuit Boards: From Early Days to Modern Innovations - Key Components and Materials: Building Blocks of Early Circuit Boards

| Component | Material | Function | Era of Use |

|---|---|---|---|

| Resistor | Carbon or Metal Film | Limits current flow | Early 1900s to Present |

| Capacitor | Ceramic or Electrolytic | Stores electrical energy | Early 1900s to Present |

| Transistor | Silicon | Amplifies electrical signals | 1940s to Present |

| Diode | Silicon or Germanium | Allows current flow in one direction | 1940s to Present |

| Integrated Circuit (IC) | Silicon | Combines multiple components into one | 1960s to Present |

| PCB Substrate | FR-4 (Glass Epoxy) | Supports and insulates components | 1970s to Present |

Technological Advancements: Milestones in Circuit Board Design

The evolution of circuit boards has been marked by significant technological advancements that have shaped modern electronics. One of the pivotal milestones in circuit board design was the introduction of multilayer boards in the 1980s. This innovation allowed for greater component density and enhanced performance in smaller form factors. According to a report by Research and Markets, the global multilayer PCB market was valued at approximately $22.6 billion in 2021, with projections indicating a growth rate of 5.7% from 2022 to 2027, highlighting the high demand for compact and efficient electronic devices.

Another key advancement was the development of flexible printed circuit boards (FPCBs), which opened new avenues for product design and functionality. The FPCB market is expected to reach $63.4 billion by 2026, as noted in a study by IDTechEx, reflecting the burgeoning use of these flexible circuits in consumer electronics, automotive, and medical applications. The ability of FPCBs to endure bending and twisting without losing performance is revolutionizing how manufacturers approach electronic design, resulting in more versatile and innovative products. As we continue to see advancements in materials and manufacturing processes, the future of circuit board design promises to bring even more remarkable innovations to the forefront of technology.

Modern Innovations: The Role of AI and Automation in PCB Development

The integration of AI and automation in printed circuit board (PCB) development marks a significant milestone in the evolution of electronic design. Companies are increasingly leveraging AI technologies to streamline the design process, enabling faster and more efficient creation of PCBs. For instance, platforms that utilize AI for the automation of PCB design are helping engineers overcome traditional challenges, such as layout optimization and component placement, with remarkable precision. This shift not only enhances productivity but also reduces the chances of human error, allowing for more complex designs to be realized within shorter timeframes.

Moreover, the impact of automation on PCB manufacturing is evident through advancements in precision equipment. Recent developments in CNC drilling machines have illustrated a growing demand for smart manufacturing solutions that meet the rising quality standards in PCB production. As the industry adapts to these innovations, the collaboration between AI technologies and traditional manufacturing processes is likely to pave the way for a new era of electronic device capabilities. This intersection of AI, automation, and PCB design not only accelerates innovation but also creates new opportunities in the ever-evolving landscape of electronics.

Future Trends: Sustainable Practices in Circuit Board Manufacturing

The landscape of circuit board manufacturing is undergoing a significant transformation as the industry pivots towards sustainable practices. Traditional methods often resulted in substantial environmental footprints, characterized by hazardous waste and excessive energy consumption. To combat these issues, companies are now focusing on eco-friendly materials and processes. For instance, the adoption of biodegradable substrates and non-toxic solder is becoming increasingly prevalent. Such innovations not only minimize environmental impact but also cater to a growing consumer demand for sustainable electronics.

Moreover, recycling initiatives are gaining momentum within the circuit board industry. Many manufacturers are implementing closed-loop systems that recover valuable metals and components from discarded boards. This not only reduces the need for virgin materials but also helps in addressing the global e-waste crisis. Additionally, advancements in additive manufacturing are enabling the production of circuit boards with less material waste, further promoting sustainability. These emerging trends signify a shift towards a more responsible approach, where technological evolution aligns with environmental stewardship, ensuring a greener future for circuit board manufacturing.

Evolution of Circuit Boards: Sustainability in Manufacturing

Related Posts

-

Understanding the Industry Standards Challenges for Best PCB Circuit Production

-

How to Master Circuit Board Design: Essential Tips for Beginners

-

Unlocking Quality: Proven Strategies to Source the Best Prototype PCB Board Suppliers Worldwide

-

The Definitive Ultimate Guide to Sourcing and Using Flex Circuits for Global Buyers

-

How to Achieve Fast and Cost-Effective PCB Prototyping for Your Product Development

-

Ultimate Guide to Choosing the Right Electronic Board: Key Metrics and Insights for Success