Blog

How to Choose the Right PCB Circuit Board for Your Project Needs

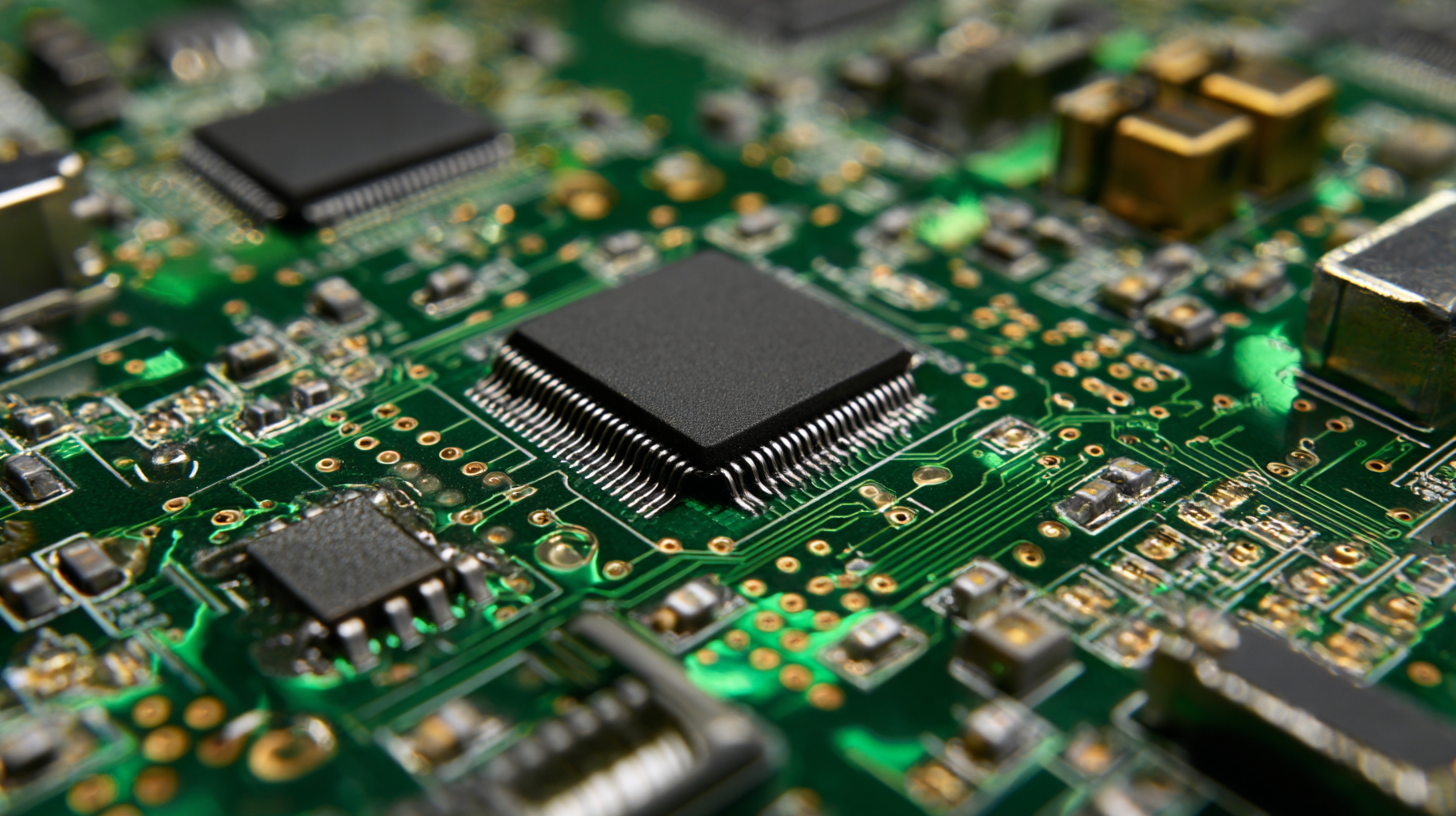

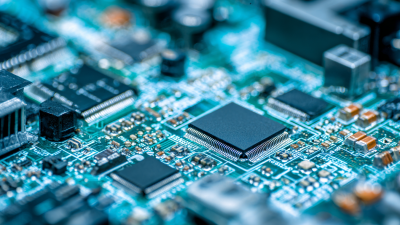

Choosing the right PCB circuit board is a crucial step in ensuring the success of any electronics project. With a plethora of options available on the market, it's essential to understand the specific requirements of your project before making a decision. Factors such as the board's size, material, layer count, and intended application all play significant roles in determining which PCB circuit board will best meet your needs. Whether you're designing a simple prototype or a complex circuit for production, the right choice can enhance functionality, reduce costs, and improve overall performance.

Choosing the right PCB circuit board is a crucial step in ensuring the success of any electronics project. With a plethora of options available on the market, it's essential to understand the specific requirements of your project before making a decision. Factors such as the board's size, material, layer count, and intended application all play significant roles in determining which PCB circuit board will best meet your needs. Whether you're designing a simple prototype or a complex circuit for production, the right choice can enhance functionality, reduce costs, and improve overall performance.

In this guide, we will explore the key considerations and components involved in selecting the ideal PCB circuit board, empowering you to make informed decisions that align with your project objectives.

Identifying Your Project Requirements for PCB Circuit Boards

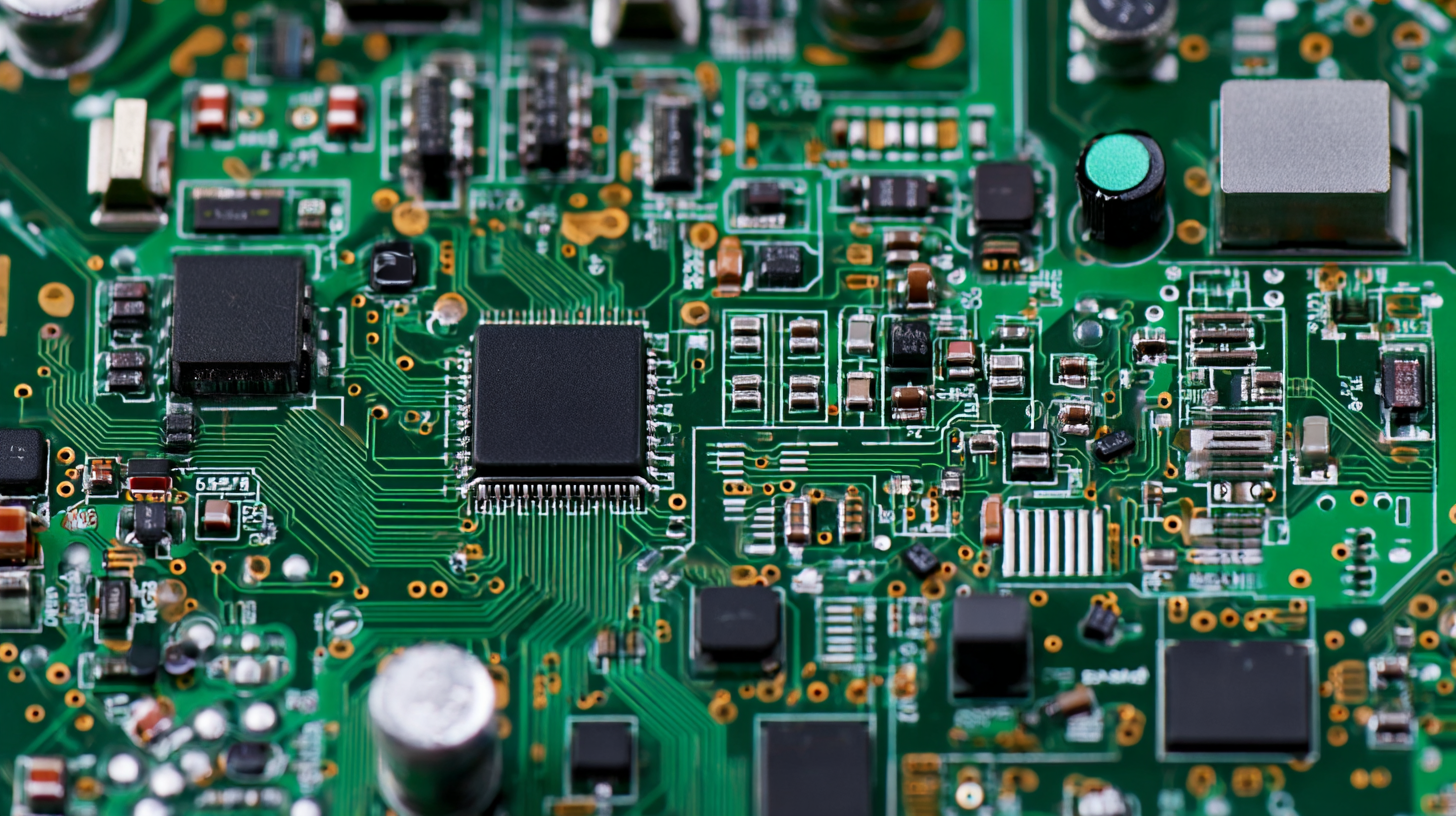

When embarking on a project that requires a printed circuit board (PCB), identifying your project requirements is crucial. Start by assessing the electrical specifications necessary for your application, such as voltage, current, and frequency. For instance, if you are designing a high-frequency circuit, selecting a PCB material with low dielectric loss is essential to ensure signal integrity. Additionally, consider the operating environment—temperature variations and exposure to humidity can drastically affect PCB performance, so material choice should account for these factors.

Another key aspect to evaluate is the physical dimensions and layout of your PCB. Analyze the space constraints and component placement to ensure optimal functionality and manufacturability. Assess the complexity of your circuit—simple designs may benefit from a single-layer PCB, while more intricate projects might require multi-layer configurations for effective routing of connections. By thoroughly examining these requirements, you can make informed decisions that lead to a more successful and efficient project.

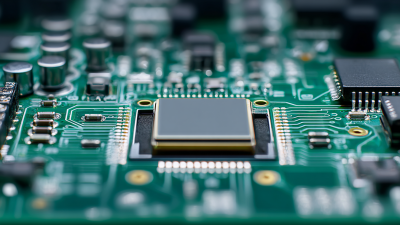

Evaluating Materials and Specifications for Durability and Performance

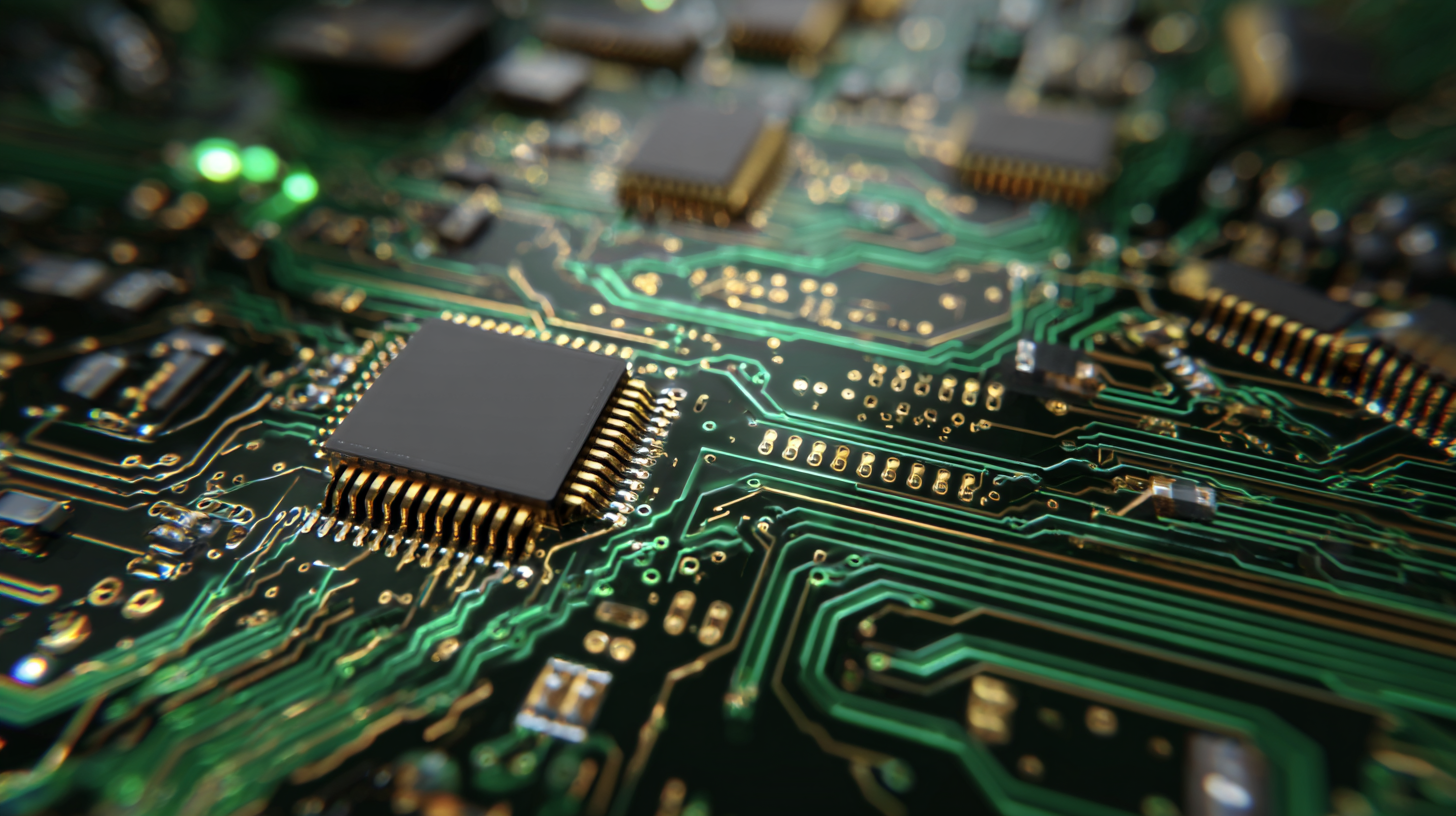

When selecting a PCB circuit board, evaluating materials and specifications is crucial to ensure durability and performance. According to a report by IPC, the global standardization organization for the electronics industry, over 60% of PCB failures can be attributed to material deficiencies. Therefore, using high-quality materials such as FR-4, which offers excellent thermal stability and dielectric properties, can significantly enhance performance. In contrast, advanced materials like polyimide are recommended for applications requiring superior heat resistance and flexibility.

Additionally, the thickness and type of copper used in the PCB can influence its electrical performance and longevity. The IPC Guidelines state that thicker copper layers (3 oz or more) are preferable for high-current applications as they improve heat dissipation and reduce the risk of oxidation. It's also essential to consider the surface finish; for instance, ENIG (Electroless Nickel Immersion Gold) provides excellent solderability and corrosion resistance, making it ideal for high-reliability applications. Understanding these material specifications and their implications can help engineers make informed decisions that enhance the overall functionality and lifespan of their projects.

Understanding Different Types of PCBs and Their Applications

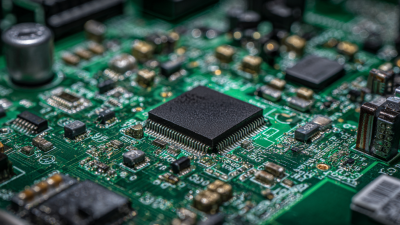

When selecting the appropriate printed circuit board (PCB) for a project, understanding the different types of PCBs and their specific applications is crucial. There are primarily four categories of PCBs: single-sided, double-sided, multi-layer, and rigid-flex. According to a report by MarketsandMarkets, the global PCB market is projected to reach $84.59 billion by 2026, reflecting the growing demand for advanced circuit board technologies. Single-sided PCBs are commonly used in simple electronic devices, such as calculators and basic household items. In contrast, double-sided PCBs facilitate more complex circuitry by allowing connections on both sides, ideal for devices that require a compact design, like smartphones and cameras.

Multi-layer PCBs take complexity a step further, enabling the layering of three or more conductive layers. This type is particularly advantageous in high-frequency applications, such as telecommunications and sophisticated computing devices. Rigid-flex PCBs combine the benefits of both rigid and flexible designs, lending themselves to applications in medical devices and aerospace where space and weight savings are critical. As per a research study from TechNavio, the rigid-flex segment is anticipated to grow at a CAGR of 7% over the next five years, illustrating its increasing importance in the PCB landscape. Understanding these distinctions will help engineers and designers make informed decisions that align with their project's specifications and budget constraints.

How to Choose the Right PCB Circuit Board for Your Project Needs

| PCB Type | Layer Count | Material | Typical Applications | Advantages |

|---|---|---|---|---|

| Single-Sided PCB | 1 Layer | FR-4 | Consumer Electronics, Simple Circuits | Cost-effective, Easy to design and manufacture |

| Double-Sided PCB | 2 Layers | FR-4 | Complex Devices, Audio Equipment | More components can be integrated, Good for dense layouts |

| Multi-Layer PCB | 3+ Layers | FR-4 or Rogers | High-Performance Computers, Telecommunication Equipment | High-density interconnections, Superior signal integrity |

| Flexible PCB | 1-2 Layers | Polyimide | Wearable Devices, Medical Equipment | Lightweight, Space-saving, Can fit into small spaces |

| Rigid-Flex PCB | 1-16 Layers | FR-4 with flexible material | Aerospace, Automotive, Medical | Combines rigidity and flexibility, Reduces connection points |

Selecting the Right Manufacturer for Quality and Cost Efficiency

When embarking on a PCB project, choosing the right manufacturer is crucial for ensuring both quality and cost efficiency. The first step is to evaluate the manufacturer's experience and reputation in the industry. Look for companies that have a proven track record with projects similar to yours. Reviewing customer testimonials and case studies can give you insight into their reliability and capabilities. Additionally, consider the certifications they hold, such as ISO or IPC, as these can indicate adherence to industry standards and quality assurance processes.

Cost efficiency is another vital aspect to consider when selecting a PCB manufacturer. It is important to obtain quotes from multiple suppliers to compare pricing structures, but pay close attention to what is included in these quotes. Some manufacturers may offer lower upfront costs but could compromise on material quality or production speed. It is essential to weigh these factors carefully, as the cheapest option may not always yield the best long-term results. Furthermore, discussing lead times and production capabilities upfront can help you find a partner that aligns with your project timeline and budget without sacrificing quality.

Ensuring Compliance with Industry Standards and Regulations

When selecting a PCB circuit board for your project, ensuring compliance with industry standards and regulations is crucial. Different sectors, such as automotive, aerospace, and medical devices, have specific requirements that must be met to ensure safety and reliability. Familiarizing yourself with standards like IPC-A-600 for printed circuit boards or ISO 9001 for quality management systems can be instrumental in guiding your selection process. Compliance not only enhances product quality but also reduces the risk of costly recalls and associated legal issues.

Furthermore, adhering to regulations such as RoHS (Restriction of Hazardous Substances) is essential, particularly in electronics manufacturing, to limit environmental impact and promote sustainability. Choosing a manufacturer who understands these legal and industry guidelines can help streamline the design-to-production process. Engaging with quality assurance experts early in your project can ensure that all aspects of the PCB design adhere to necessary compliance measures, ultimately safeguarding your project’s success in a competitive market.

Related Posts

-

How to Choose the Best PCB Board for Your Project Needs

-

7 Essential Tips for Sourcing the Best PCB Production Worldwide

-

Discover the Excellence of Best PCB Make from Top Quality Manufacturers in China

-

Unlocking the Advantages of Using Prototype PCB Boards in Modern Electronics Design

-

How to Achieve Fast and Cost-Effective PCB Prototyping for Your Product Development

-

7 Essential Reasons Why Rigid Flex Technology Is Transforming Modern Electronics